|

Bakelite, "The material of a thousand uses," as it was called, made a splash

in the 1920s, '30s and '40s. Bakelite combined carbolic acid and formaldehyde to produce a versatile substance such as phenolic

resin or "Bakelite," a revolutionary, non-flammable, early plastic. Philco utilized the Bakelite block condensers (in the

vintage vernacular) throughout the 1930s. It is a feature unique to Philco.

You can reference other sites that deal

with the subject (RELATED LINKS). I thought, as a newbie to the hobby I would provide my perspective.

(1)

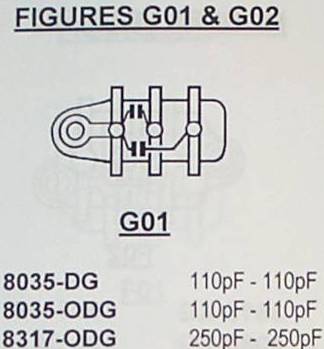

DO NOT START WITHOUT SPECS. such as this reference by Ray

Bintliffs, Philco Condensers and More 2nd Edition, available through Antique Electronic Supply.

KNOW the capacitor's wiring configuration and DO NOT rely on reverse engineering

as you disassemble. It will become confusing. Also, the capacitor may have a resistor

embedded within. Check the references. No reference? Contact Me

(3)

The underside of this cap has not been seen in 70+ years. The caps are sealed

in a hard wax/tar mixture with the approximate hardness of ice.

(5)

Cleaned out and ready to re-stuff and seal. Again, picking out the tar is the

cleanest method. The material flecks out in chunks. (Note the sheen on the inside of the cap.)

(6)

Old connections are de-soldered, wire brushed, and ready for new caps installation,

sealing, and re-installation into the circuit.

(8)

The new caps inserted into the Bakelite shell,

(10)

connections soldered in,

|